Photo by Thimo Pedersen on Unsplash

The next decade is going to be all about enhanced digital experience built on top of the most advanced wireless data communications technologies ever: 5G and Wi-Fi 6.

These two wireless technologies are not only going to increases the data throughput but also provide much better connectivity experience with minimum power impact, thus making them suitable from home to industry-wide applications.

5G has already started to take over the world and along with Wi-Fi 6 proliferation, the always-on connectivity is going to ease day to day information-enabled digital life.

WHAT IS 5G

5G is the next generation of voice and data communication solution that is capable of providing 20x more data speed compared to current 4G deployed all over the world. It does so by enabling low latency by deploying a wide array of networks that allows multiple users with multiple inputs and multiple output data transmission.

5G is also capable of running at a different spectrum from below 1GHz to above 24GHz.

WHAT IS Wi-Fi 6

Wi-Fi 6 is the next IEEE 802.11ax standard designed for the future data, increasing nodes and security needs. It is going to provide much better seamless connectivity without getting affected by the number of active users. It can do so by providing high capacity via Orthogonal Frequency-Division Multiple Access (OFDMA) with minimal energy requirements.

Poor connectivity and network interference at home and offices are going to be a thing of past with Wi-Fi 6. Wi-Fi 6 is capable of using both 2.4 and 5 GHz frequencies. With recently introduced Wi-Fi 6E which supports 6GHz may allow easy interoperability with 5G.

One of the benefits of Wi-Fi 6 is its backward compatibility, which allows previous Wi-Fi generation devices to work with Wi-Fi 6 certified products. For better user experience, it is always good to have all the infrastructure upgraded with both transmitting and receiving systems capable of running Wi-Fi 6 protocol.

5G vs Wi-Fi 6

It is often said that 5G and Wi-Fi 6 are supposed to compete for the same services. In reality, 5G is designed specifically to cater to the mobility needs, while Wi-Fi 6 for better location aware requirements.

5G will dominate on-the-go connectivity by providing faster data and voice speed. Wi-Fi 6 on other hand will cater to the smart solution (while taking the help from 5G) without worrying about the number of nodes, access points, and security.

In the end, 5G and Wi-Fi 6 are going to work in harmony and create value for the next digital decade.

5G IS FOR THE OUTER WORLD

Every wireless technology has a perfect use case. Near-Field Communication is designed for secure transactions like paying via NFC enabled credit card or Mobile Wallet. Same is true for Bluetooth which is designed for short-range communication like connecting to streaming devices or car’s infotainment.

Similarly, 5G has been designed and developed over the last decade with future demand in mind. It is going to be the de-facto wireless solution for anything that requires a remote connection. Whether it is the remotest place that requires high-speed data to enabling cross reality in places where it is difficult today. It will also ensure that digital education is accessible at affordable cost to anyone with 5G equipment and networks.

5G is going to benefit both consumers and businesses due to the real-time fastest possible access to the data. Smart cities around the world will provide public service on top of 5G networks from remote kiosks to online utility access and payment solutions.

Over The Top (OTT) is a terminology that allows content to thrive, scale, and monetize on top of an existing technological solution. Not only 5G is going to enable software-driven OTT, but many hardware OTT are also going scale on top of 5G.

All of this is going to enable the next trillion-dollar market with huge employment opportunities for every sector.

Wi-Fi 6 FOR THE INNER WORLD

While 5G is supposed to transform the outer world, Wi-Fi 6 is going to enhance the experience of indoor digital activity to the next level.

There are fundamentally bigger differences between 5G and Wi-Fi 6. One of the simplest to understand is that 5G requires full infrastructure upgrade including smart devices like smartphones. On the other hand Wi-Fi 6 is about connecting to the access point with Wi-Fi 6 protocol enabled and thereby leveraging existing high-speed bandwidth network. This is why Wi-Fi 6 is more suitable for the inner world like home, public areas, offices, and schools as these are already equipped with high speed wired networks.

For Wi-Fi 6 too full upgrade of receiver and transmitter (Wi-Fi 6 certified) is preferred, however since it is backward compatible thus only one device (receive/transmitter) needs to be using Wi-Fi 6 certified. However, from technical point of view it still doesn’t mean full Wi-Fi 6 experience. With Wi-Fi 6, the routers will allow better performance irrespective of number of active IoT devices. WPA3 (security standard used by Wi-Fi 6) will also ensure the secure transaction are more hack-proof.

Only time will tell if the routers itself will be used as hardware devices that will run more digital applications thus ushering new ways to provide OTT services. In any case, new era of home connectivity will enrich digital experience.

HURDLES WITH OPPORTUNITIES

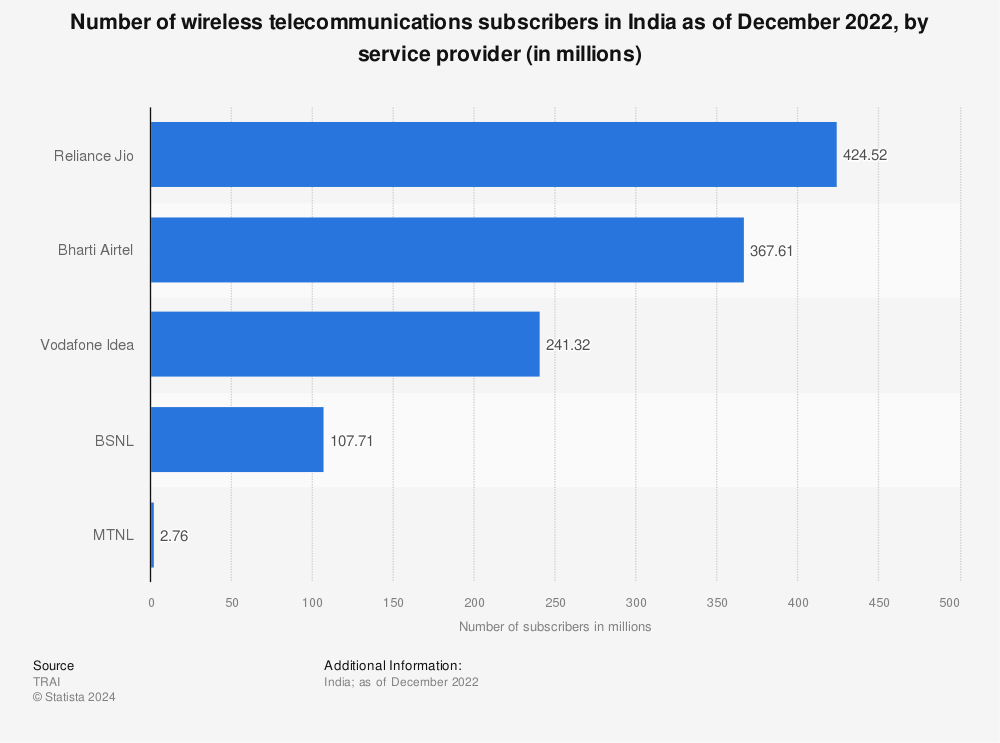

The biggest hurdle for both 5G and Wi-Fi 6 is to ensure that not only new devices are capable of communicating using the two new protocol but the infrastructure required to deliver the true promises these two solutions hold is deployed massively across the globe. It will be critical to implement in India, where millions of users are still using 3G and older Wi-Fi certified devices.

For 5G, the smart devices need to have electronic chips capable of encoding/decoding the packets that will be sent to and from the nearby cell towers. Telecom operators will have to invest and upgrade all of the networks to ensure 5G protocols can run smoothly on top of the existing 4G infrastructure. Given that some countries still have more than 350 million 2G users, it will take half a decade to move many of the current 3G/4G users to 5G.

Wi-Fi is backward compatible, thus it only needs one of the two communicating devices to be running on the newer protocol. However, OEMs have started launching laptops, smartphones, and smart devices with Wi-Fi 6. Network equipment also have started to come Wi-Fi 6 certified. Similar to 5G, Wi-Fi 6 large scale adoption is also expected to take more than half a decade as many business that are going through the financial impact due to COVID-19 will be focusing more on revenue re-generation than upgrading existing infrastructure at large.

With hurdles come opportunities. Upgrading all the devices (or one of the nodes for Wi-Fi 6) that will access these protocols at different frequencies, also means tremendous revenue opportunity from OEMs to Distributors. It will also provide platform for the new markets to tap into the hardware manufacturing and assembly opportunities.

Another possibility is merging 5G with Wi-Fi 6E (a step ahead of Wi-Fi 6), and that is going to ensure that the investment to implement these infrastructure today pays off in the long term when devices and nodes can easily switch between these two wireless frequency technology without upgrading.

It may also drive innovation as both 5G and Wi-Fi 6E solutions can reside on the same System-On-Chip, thus allowing optimization on the designing and reducing manufacturing cost.

DIGITAL TRANSFORMATION ROAD MAP

As the world moves towards post-COVID-19 new normal, digital connectivity across the globe will be the priority. Governments will push for newer and better wireless connectivity to enable end-to-end digital transformation road map. 5G and Wi-Fi 6 are going to ensure that every digital offering is experience the new innovation.

The digital transformation road map will be a 360-degree view on how daily home to business to industry activity is going to be always-on data enabled. Whether it is accessing information at home, commuting to the office, shopping at local stores, running in the park, producing products in heavy industry, going for health check-ups to making cities smarter.

All of this is going to drive change, thus allowing 5G And Wi-Fi 6 to transform digital life.

For the technical audience:

- A Brief Overview of 5G Research Activities research paper by Prof. Pekka Pirinen provides an interesting summary of different research and development activities on and around 5G.

- Research around Wi-Fi 6 is still gaining momentum, however the research paper A Tutorial On IEEE 802.11ax High-Efficiency WLANs by Evgeny Khorov et. al. provides an informative tutorial on Wi-Fi 6 IEEE 802.11ax standard.